Gilashin shara wani nau'in sharar gida ne, kasancewarsa ba wai kawai yana haifar da lahani da rashin jin daɗi ga samar da mutane da rayuwar su ba, har ma yana kawo gurɓatawa ga muhalli, yana mamaye ƙasa mai mahimmanci, kuma yana ƙara nauyin muhalli. An kiyasta cewa China tana samar da kimanin tan miliyan 3.2 na gilashin shara kowace shekara, wanda ya kai kusan kashi 2% na jimlar sharar birni. Tare da haɓaka ƙarfin ƙasa mai ƙarfi da inganta rayuwar mutane, jimlar adadin gilashin shara ya ƙaru. Dangane da sake amfani da gilashin shara da amfani da su, wasu ƙasashe masu tasowa a Burtaniya da Amurka sun sami sakamako mai ban mamaki. Ƙasashen Turai da Amurka sun yi nasarar amfani da gilashin shara a ayyukan gini, wanda hanya ce mai inganci don cinye gilashin shara mai yawa. Saboda ba a buƙatar a ware kowane nau'in gilashin shara, babu buƙatar launi. Misali, ana sarrafa gilashin shara azaman kayan ado na gini a cikin Mosaic. A matsayin masana'antar injinan gilashin shara, injinan gilashin shara da HCM Machinery ke samarwa yana ba da taimako mai kyau ga kayan aiki don sake amfani da gilashin shara. A yau, za mu gabatar da tsarin samar da gilashin sake amfani da gilashin shara Mosaic.

1. Fa'idar dutsen phosphate: Fa'idar dutsen phosphate shine mataki na farko a cikin sarrafa dutsen phosphate, wanda ke da nufin raba ma'adanai masu amfani daga ƙazanta a cikin dutsen phosphate ta hanyar hanyoyin zahiri da na sinadarai. Hanyoyin fa'idar gama gari sun haɗa da raba nauyi, fa'idar flotation da rabuwar maganadisu. Raba nauyi yana amfani da bambancin yawa na ma'adanai a cikin ma'adinai don rabuwa, fa'idar flotation yana amfani da bambancin buoyancy na ma'adanai a cikin ma'adinai don rabuwa, kuma rabuwar maganadisu yana amfani da bambancin maganadisu na ma'adanai a cikin ma'adinai don rabuwa.

2. Niƙa da niƙa dutsen phosphate: dutsen phosphate bayan an gama shi, ana buƙatar a niƙa shi da kuma niƙa shi, domin ya fi kyau a fitar da ma'adanai masu amfani a cikin ma'adinan. Yawanci ana amfani da niƙa muƙamuƙi, mazugi da sauran kayan aiki don karya dutsen phosphate zuwa girman barbashi da ya dace. Niƙa shine amfani da injin niƙa mai girma da sarrafa injin niƙa na phosphate don niƙa ma'adinan da aka niƙa da kyau, don ya cika buƙatun fineness da ake buƙata.

3. Zubar da dutsen phosphate: Zubar da dutsen phosphate muhimmin mataki ne a cikin sarrafa dutsen phosphate, wanda ta hanyarsa ake iya narkar da sinadarai masu amfani kamar phosphate daga ma'adinan. Hanyoyin zubar da acid da aka saba amfani da su sun hada da zubar da acid, zubar da alkaline da kuma zubar da oxidation. Zubar da acid yana amfani da maganin acid don narkar da phosphate, zubar da alkaline yana amfani da maganin alkaline don narkar da phosphate, kuma zubar da oxidative yana amfani da maganin oxidizing don narkar da phosphate.

4. Ruwan sama da tace ma'adanai na phosphate: Bayan an cire ruwa, ana buƙatar a tace ruwan da ke ɗauke da sinadarai masu amfani kamar phosphate don raba samfuran phosphate masu ƙarfi. Ruwan sama shine amfani da sinadarin da ke fitar da ruwa don canza sinadarin phosphate na maganin zuwa wani abu mai ƙarfi, kuma tacewa shine raba laka daga maganin ta hanyar tace kayan aiki.

5. Busar da dutsen phosphate da kuma tace shi: Bayan an tace shi, sai a busar da shi a kuma tace shi domin a sami samfurin phosphate da aka gama. Busarwa ita ce amfani da kayan busarwa don fitar da ruwan da ke cikin laka, kuma yin siminti shine busar da laka a lokacin da ake yin siminti mai zafi, ta yadda zai samar da barbashi masu yawa na phosphate.

6. Maganin tabar wiwi ta phosphate: Tsarin sarrafa tabar wiwi ta phosphate zai samar da wani adadin tabar wiwi, tabar wiwi tana ɗauke da ma'adanai da ƙazanta marasa cirewa. Domin rage gurɓatar muhalli da ɓarnatar albarkatu, ana buƙatar a magance tabar wiwi. Hanyoyin magance tabar wiwi na yau da kullun sun haɗa da tara tabar wiwi, sake amfani da tabar wiwi da kuma amfani da tabar wiwi cikakke.

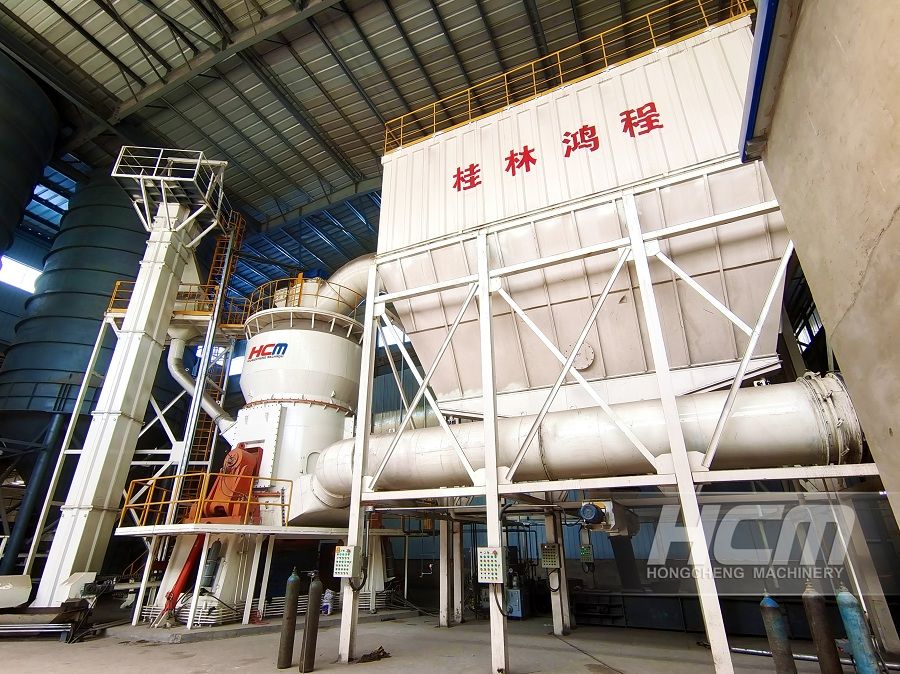

Tsarin samar da gilashin sharar gida mai amfani da gilashin Mosaic: hanyar yin sintering da hanyar narkewa gabaɗaya ana amfani da su, kuma hanyar samar da hanyar yin sintering da mosaic na yumbu iri ɗaya ne. Babban tsarin samarwa shine a niƙa gilashin sharar gida ta injin niƙa gilashin sharar gida don biyan buƙatun ƙanƙantar foda na gilashin, sannan a ƙara wani adadin mai mannewa (gwangwani mara tsari ko na halitta) da kuma mai canza launi ko mai canza launi, tare da mahaɗin don haɗa shi zuwa wani mahaɗi iri ɗaya. Ana matse cakuda a cikin siffofi daban-daban na geometric ta hanyar matse busasshe, kuma ana aika busasshen jikin zuwa murhun birgima, murhun farantin turawa da murhun rami tare da zafin digiri 800-900 Celsius don yin sintering. Gabaɗaya, yana zama a yankin zafin sintering na awanni 1.5-2.5. Ana sanyaya kayayyakin daga murhun don dubawa, sanya su, busarwa, dubawa, marufi, ajiya ko masana'anta, ana sake yin amfani da samfuran da ba su cancanta ba. Hanyar narkewar ta dogara ne akan gilashin sharar gida (yawan mutanen shine 25-60%) a matsayin babban kayan da aka yi amfani da shi, ana ƙara wani adadin yashi na silica, feldspar, farar ƙasa, ash na soda da kuma wakili na emulsion, mai canza launi ta hanyar injin niƙa gilashin sharar gida zuwa foda mai dacewa iri ɗaya, sannan a cikin tanda mai zafi (zafin narkewa shine 1400-1500) don narkewa ya zama ruwan gilashi iri ɗaya. Ruwan gilashin yana gudana cikin kalanda kuma ana matse shi cikin wani tubalin gilashi mai girman da siffa, wanda ake aika shi zuwa murhun annealing. Ana iya adana ko isar da kayayyakin annealed bayan dubawa, sanyawa da marufi.

Sake Amfani da Gilashin Shara Mosaics na gilashi an gina su ne akan niƙa gilashin shara zuwa foda gilashi. Injin niƙa gilashin shara kayan aiki ne na samarwa don sarrafa foda gilashi. Injin niƙa gilashin shara wanda aka samar ta hanyarInjin HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Lokacin Saƙo: Janairu-08-2024