Tsarin da Ka'ida

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne manyan dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayinmu na kamfani mai matsakaicin girma a duniya don CaCO3 Roller Grinding Plant Raymond Mill don Kaolin Mica Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line, Kamfaninmu yana da sha'awar kafa hulɗar abokan hulɗa na dogon lokaci da taimako tare da abokan ciniki da 'yan kasuwa daga ko'ina cikin duniya.

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne muhimman dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayin kamfani mai matsakaicin girma a duniya donInjin Gypsum, Injin Niƙa Kaolin, Kaolin Raymond Mill, Injin niƙa na MicaKamfaninmu yana aiki ne bisa ka'idar aiki ta "bisa gaskiya, haɗin gwiwa da aka ƙirƙira, wanda ya mayar da hankali kan mutane, haɗin gwiwa da cin nasara". Muna fatan za mu iya samun kyakkyawar alaƙa da ɗan kasuwa daga ko'ina cikin duniya.

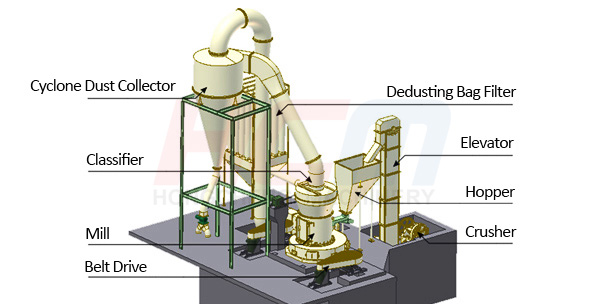

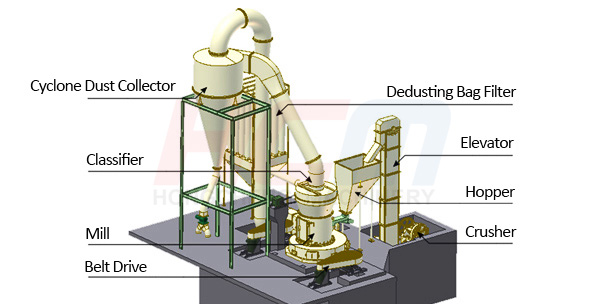

Injin naɗa na'urar R-series galibi ya ƙunshi babban injin niƙa, injin bincike, injin hura iska, lif ɗin bokiti, injin niƙa muƙamuƙi, mai ciyar da na'urar lantarki mai girgiza, injin sarrafa wutar lantarki, mai raba guguwar da kayan aikin bututun iska, da sauransu.

Yayin da injin niƙa ke aiki, ƙarfin centrifugal yana tura biredi zuwa saman ciki na tsaye na zoben niƙa. Gasa yana juyawa tare da haɗuwa yana ɗaga kayan ƙasa daga ƙasan injin niƙa kuma yana jagorantar shi tsakanin biredi da zoben niƙa inda aka niƙa shi. Iska tana shiga daga ƙasan zoben niƙa kuma tana kwarara sama tana ɗauke da tabo zuwa ɓangaren rarrabuwa. Mai rarrabawa yana ba da damar kayan girman su wuce zuwa ga mai tattara kayan kuma yana dawo da ƙananan barbashi marasa cancanta zuwa ɗakin niƙa don ƙarin sarrafawa. Injin niƙa yana aiki a ƙarƙashin yanayi mara kyau, yana rage kula da injin niƙa da kula da kayan shuke-shuke yayin da yake haɓaka tsawon rayuwar manyan kayan injin.

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne manyan dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayin kamfani mai matsakaicin aiki a duniya don Masana'anta kai tsaye China CaCO3 Roller Grinding Plant Raymond Mill don Kaolin Mica Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line, Kamfaninmu yana da sha'awar kafa hulɗa ta dogon lokaci da taimako tsakanin abokan hulɗa na kasuwanci da abokan ciniki da 'yan kasuwa daga ko'ina cikin duniya.

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne manyan dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayin kamfani mai matsakaicin aiki a duniya don Masana'anta kai tsaye China CaCO3 Roller Grinding Plant Raymond Mill don Kaolin Mica Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line, Kamfaninmu yana da sha'awar kafa hulɗa ta dogon lokaci da taimako tsakanin abokan hulɗa na kasuwanci da abokan ciniki da 'yan kasuwa daga ko'ina cikin duniya.

Masana'anta kai tsaye a China Injin niƙa, Injin niƙa, Kamfaninmu yana aiki ne bisa ƙa'idar aiki ta "tushen mutunci, haɗin gwiwa da aka ƙirƙira, wanda ya mayar da hankali kan mutane, haɗin gwiwa da cin nasara". Muna fatan za mu iya samun dangantaka mai kyau da ɗan kasuwa daga ko'ina cikin duniya.

Muna so mu ba ku shawarar mafi kyawun samfurin injin niƙa don tabbatar da cewa kun sami sakamakon niƙa da ake so. Da fatan za a gaya mana waɗannan tambayoyin:

1. Kayanka na asali?

2. Ana buƙatar fineness (raga/μm)?

3. Ƙarfin da ake buƙata (t/h)?

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne manyan dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayin kamfani mai matsakaicin aiki a duniya don Masana'anta kai tsaye China CaCO3 Roller Grinding Plant Raymond Mill don Kaolin Mica Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line, Kamfaninmu yana da sha'awar kafa hulɗa ta dogon lokaci da taimako tsakanin abokan hulɗa na kasuwanci da abokan ciniki da 'yan kasuwa daga ko'ina cikin duniya.

Kirkire-kirkire, kyakkyawan aiki da kuma aminci su ne manyan dabi'un kasuwancinmu. Waɗannan ƙa'idodi a yau sun fi kowane lokaci tushen nasararmu a matsayin kamfani mai matsakaicin aiki a duniya don Masana'anta kai tsaye China CaCO3 Roller Grinding Plant Raymond Mill don Kaolin Mica Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line, Kamfaninmu yana da sha'awar kafa hulɗa ta dogon lokaci da taimako tsakanin abokan hulɗa na kasuwanci da abokan ciniki da 'yan kasuwa daga ko'ina cikin duniya.